Trunnion ball valves

Production Range

| API603/ASME 16.34 | API600/BS1414 | ||

| Class | Size | Class | Size |

| 150 | 2″~ 12″ | 150 | 2″~ 24″ |

| 300 | 2″~ 12″ | 300 | 2″~ 16″ |

| 150 | 2″~ 12″ | 600 | 2″~ 24″ |

| 900 | 2″~ 24″ | ||

| 1500 | 2″~ 24″ | ||

Design Standards

| Pressure-Temperature rating | ANSI B16.34 |

| Face to Face Dimensions | ANSI B16.10 |

| End Flange Dimensions | ASME B16.5 |

| Testing | API598/MSS-SP-41 |

| Bonnet Bolt | ASTM A193/ ASTM A320 |

| BonbetNut | ASTM A194 |

| Marking | MSS-SP-25 |

| Light wall Thickness | API603/ANSI B16.34 |

| Heavy Wall thickness | PI 600/ BS 1873 |

Seat Sealing

Soft seats are standard. Seat inserts of synthetic material such as Nylon,PTFE, RTFE or Peek are containedwithin a metal seat ring. With no orvery low line pressure, sealing betweenthe seats and ball is achieved by seatsprings. With higher line pressure, theline pressure, in conjunction with thespring load, forces the upstream seatring against the ball, which results intighter sealing.0-ring seat insertdesign is available.

Self Reli eving Seat

This standard feature is designed to prevent excessive pressure buildupwithin the valve by automaticallyrelieving pressure when body cavitypressure exceeds the spring load onthe seatsDouble Piston Seat is also available asan option.

Sealant Inject Fitting

This feature is standard except in sizes 2″-4″ for pressure classes 150,300and 500, In case of seat ring damage,sealant injection provides a fast,reliable way to restore tight sealing,This injection system can also be usedfor routine flushing of the seat ring areawhile in service.

Double Seals at all joints

All connecting parts employ a doublr sealing design incorporating a spiralwound 316ssigraphite gasket ando-ring to ensure positive sealing.Delta ring is used optionally for class1500-2500.

Stem Sealing&Sealant lnjection Fitting

Two o-rings and graphite packing are used for pressure classes 150through 600. One each of lipseal ando-ring plus graphite packing are usedfor pressure classes 900 through2500, In case of damage to the o-rirglipseal, sealant injection stops leakingand restores tight sealing

Seat Ring Sealing

All connecting parts employ a double sealing design incorporating a spiralwound 316ssigraphite gasket ando-ring to ensure positive sealing.Delta ring is used optionally for class1500-2500

Actuation

JMC® Trunnion ball valves are designed to easily install a variety of actuatots including pneumatic,hydraulic, electric actuators, electro-mechanical, electro-hydraulic, vane, Hand operated valves are normally etc supplied with a lever or gear operator High-performance hydraulic actuators, which have been specialty developed for JMC® trunnion ball valves, can be supplied directly from SAMJIN JMCFurther information can be received on request.

Double Block and Bleed

JMC㉧ Trunnion ball valves provide a positive seal at both upstream and downstream independently, Since pressure on each side of the ball is blocked from the body cavity, a pressure releasing device can be used by an operator to check the integrity of the upstream anddownstream seats

Low Friction Stem/Trunnion Bea rings and Thrust WRshers

Heavy duty PTFE lined carbon or stainless steel bearing and thrust washers ensure durable and low torque operation.

Other Features

-Anti Static Device for Grounding

-ISO5211 Mounting pad and Adaptability forall types of Actuator mounting

-Blow-Out Proof Stem

-Stem extension pieces or pups

Standard Material Specifications

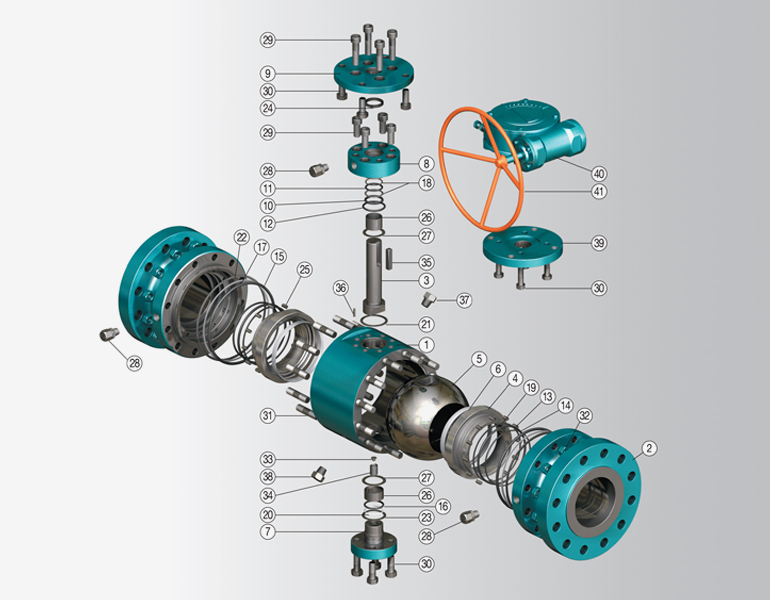

| NO | Part Name | CarbonSteel NACE | Low Temp NACE | Stainless Steel NACE |

| 1 | Body | A105 | A350 LF2 | A182 F316 |

| 2 | Cap | A105 | A350 LF2 | A182 F316 |

| 3 | Stem | AISI 1020+ENP | AISI 4140+ENP/A182 F316 | A182 F316/A564 630 |

| 4 | Seat Ring | A105+ENP | A350 LF2+ENP/A182 F316 | A182 F316 |

| 5 | Ball | A105+ENP | A350 LF2+ENP/A182 F316 | A162 F316/A351 CF8M |

| 6 | Seat Insert | |||

| 7 | Trunnion | AISI 1020/A105+ ENP | AISI 4140/A350 LF2+ ENP | A479 361 |

| 8 | Gland | AISI1020/A105 | AISI 4140/A350 LF2 | A479 361 |

| 9 | Adapter Plate | AISI1045 | HNBR/Polymite/Viton GLT | A479 361 |

| 10 | Sten O-ring * | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 11 | Stem Sub-seal** | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 12 | Gland O-ring* | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 13 | Seat O-ring* | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 14 | Seat Sub-seal** | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 15 | Cap O-ring* | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 16 | Trunnion O-ring* | Viton A | HNBR/Polymite/Viton GLT | HNBR/Viton GLT |

| 17 | Cap Backup Ring | PTFE/Nylon | PTFE/Nylon | PTFE/Nylon |

| 18 | Gland Baxkup Ring | PTFE/Nylon | PTFE/Nylon | PTFE/Nylon |

| 19 | Seat Backup Ring | PTFE/Nylon | PTFE/Nylon | PTFE/Nylon |

| 20 | Trunnion Backup Ring | PTFE/Nylon | PTFE/Nylon | PTFE/Nylon |

| 21 | Gland Seal | Spiral Wound Gasket 316SS + Graphite | ||

| 22 | Cap Seal | Spiral Wound Gasket 316SS + Graphite | ||

| 23 | Trunnion Seal | Spiral Wound Gasket 316SS + Graphite | ||

| 24 | Stem Packing | Graphite | ||

| 25 | Seat Spring | inconel X-750 | ||

| 26 | Bearing | SS316+PTFE/Carbon Steel+PTFE | ||

| 27 | Thrust Washer | SS316+PTFE/Carbon Steel+PTFE | ||

| 28 | Sealant Fitting | AISI 4140/A479 316 | ||

| 29 | Socket Bolt | A193 B7M | A320 L7M | A193 B8M |

| 30 | Hex/Socket Bolt | A193 B7M | A320 L7M | A193 B8M |

| 31 | Stud Bolt | A193 B7M | A320 L7M | A193 B8M |

| 32 | Hex.Nut | A194 2HM | A194 7M | A194 8M |

| 33 | Grounding Pin | A479 316 | ||

| 34 | Grounding Spring | A479 316 | ||

| 35 | Key | AISI 1045 | A479 316 | |

| 36 | Dowel Pin | AISI 1045 | A479 316 | |

| 37 | Relief Plug | A105 | A182 F316 | |

| 38 | Drain Plug | A105 | A182 F316 | |

| 39 | Mounting Plate | AISI 1045 | A182 F316 | |

| 40 | Gear Operator | A536 Case / A322 Worm Gear | ||

| 41 | Hand Wheel | A53 | ||