Floating ball valves

Production Range

| API603/ASME 16.34 | API600/BS1414 | ||

| Class | Size | Class | Size |

| 150 | 2″~ 12″ | 150 | 2″~ 24″ |

| 300 | 2″~ 12″ | 300 | 2″~ 16″ |

| 150 | 2″~ 12″ | 600 | 2″~ 24″ |

| 900 | 2″~ 24″ | ||

| 1500 | 2″~ 24″ | ||

Design Standards

| Pressure-Temperature rating | ANSI B16.34 |

| Face to Face Dimensions | ANSI B16.10 |

| End Flange Dimensions | ASME B16.5 |

| Testing | API598/MSS-SP-41 |

| Bonnet Bolt | ASTM A193/ ASTM A320 |

| BonbetNut | ASTM A194 |

| Marking | MSS-SP-25 |

| Light wall Thickness | API603/ANSI B16.34 |

| Heavy Wall thickness | PI 600/ BS 1873 |

Stem Sealing Design

JMC® floating ball valves are designed to prevent leakage from the stem area due to a double sealing stem systemwith two gland packing and graphite. JMC® Class 600floating ball valves have 0-rings with the double sealingstem design of graphite and carbon fiber seals to providetight sealing in high pressure and temperature, Thepacking is externallt adjustable so that even with anactuator attached it can be easily tightened.

ISO5211 Actuator Mounting

Machined top mounting pad provides precise mounting of actuator or gear box, Exact alignment allows reducing torque requirements and prevents out-of-line wear Actuators can be supplied directly from SAMJIN JMC onrequest.

Blowout-Proof stem and Metal-To-Metalseal

A stem has a shoulder as an integral part of stem, Due to such a specific structure the stem is not forced out evenwhen abnormal pressure is generated or the bolts becomeloose. When the stem packing burns out due to a fire, thestem is pressed against the body and prevent leakage toatmosphere.

Doublesealing Design and Metal-To-Met31seal

JMC㉧ Floating bali valves are constructed to have a metal contact and double sealing design with PTFE and graphitegasket, The sealing effect can be maintained even whenthe graphite burns out. The seats have a groove at theprofile back for superior sealing, which can provideexcellent sealing.

Secondary Metal Seat

In the event the primary soft seal is destroyed in a fire, JMC㉧ Floating bali valves effectively form the secondarymetal seat, which prevents leakage and the fire spreading.

Metal-To-MetalSeal

JMC㉧ floating ball valves are designed to have the dual sealing design with gasket and metal-to-metal contact atthe connection of body and body cap, which preventpossible leakage from temperature changes or line stress.The sealing is maintained even when the gasket isdestroyed in a fire. JMC㉧ Floating ball valves comply andare certified to API 607/6FA.

Anti-Static Design

Ball-spring devices are retained to allow the ststic charges to be led to the piping, which prevents static spark.

Standard Material Specifications

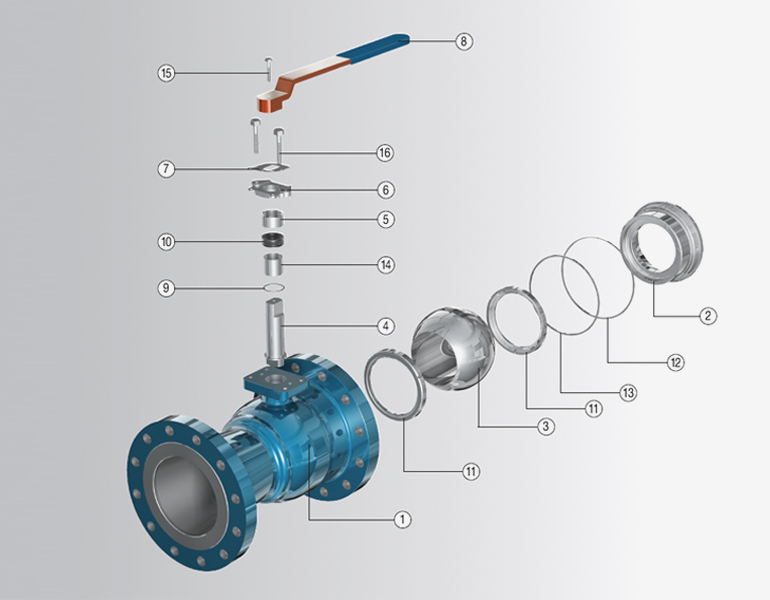

| NO | Part Name | Q’ty | Carbon Steel | Stainless Steel |

| 1 | Body | 1 | A213-WCB | A351-CF8M |

| 2 | Retainer | 1 | A213-WCB | A351-CF8M |

| 3 | Ball | 1 | A351-CF8M | A351-CF8M |

| 4 | Seam | 1 | A276-316 | A276-316 |

| 5 | Gland | 1 | A276-304 | A176-304 |

| 6 | Seat Insert | 1 | A167-304 | A167-304 |

| 7 | Trunnion | 1 | A167-304 | A167-304 |

| 8 | Handle | 1 | DUCTILE CAST IRON | |

| 9 | Thrust Washer | 1 | A213-WCB | A351-CF8M |

| 10 | Gland packing | 1 | A213-WCB | A351-CF8M |

| 11 | Seat | 1 | A351-CF8M | A351-CF8M |

| 12 | Gasket | 1 | A276-316 | A276-316 |

| 13 | Gasket | 1 | A167-304 | A176-304 |

| 14 | Stem Bearing | 1 | A167-304 | A167-304 |

| 15 | Handle Bolt | 1 | A167-304 | A167-304 |

| 16 | Gland Bolt | 1 | DUCTILE CAST IRON | |

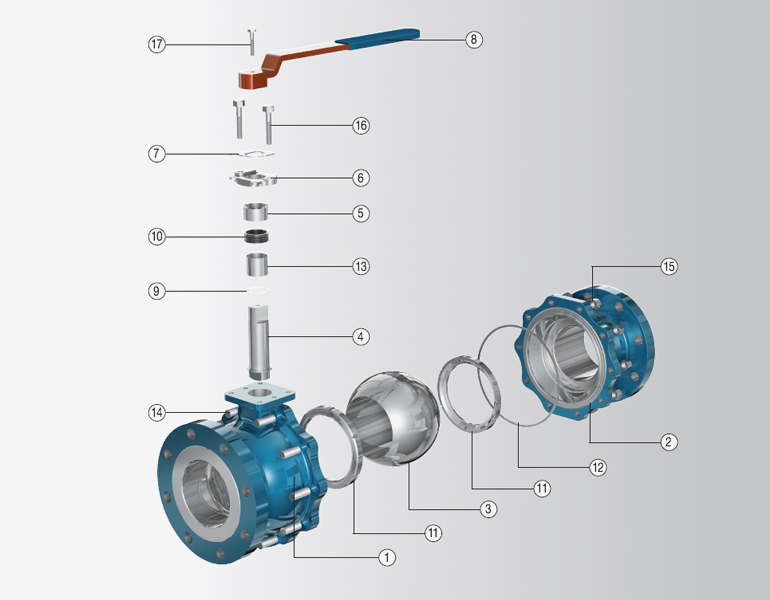

| NO | Part Name | Q’ty | Carbon Steel | Stainless Steel |

| 1 | Body | 1 | A216-WCB | A351-CF8M |

| 2 | Retainer | 1 | A216-WCB | A351-CF8M |

| 3 | Ball | 1 | A351-CF8M | A351-CF8M |

| 4 | Seam | 1 | A276-316 | A276-316 |

| 5 | Gland | 1 | A276-304 | A276-304 |

| 6 | Seat Insert | 1 | A351-CF8 | A351-CF8 |

| 7 | Trunnion | 1 | A167-304 | A167-304 |

| 8 | Handle | 1 | DUCTILE CAST IRON | |

| 9 | Thrust Washer | 1 | PTFE | PTFE |

| 10 | Gland packing | 1Set | Graphite+Carbon Fiber | Graphite+Carbon Fiber PTFE |

| 11 | Seat | 2 | A213-WCB | Super Teflon |

| 12 | Gasket | 1 | A351-CF8M | 316Hoop+Graphite |

| 13 | Gasket | 1 | A276-316 | RTFE |

| 14 | Stem Bearing | 1Set | A276-304 | A193-B8M |

| 15 | Handle Bolt | 1Set | A167-304 | A194-8M |

| 16 | Gland Bolt | 2 | A167-304 | A193-B8M |

| 17 | Handle Bolt | 1 | A193-8M | A193-8M |